WHAT IS AN MR DAMPER

MR dampers are similar in construction to fluid viscous dampers and utilize MR fluids instead of hydraulic oil. They are widely used in machines, automobiles, and civil engineering applications due to their low power consumption, quick response, easy control, and adjustable damping force.

In an MR damper, the piston includes coils capable of delivering a magnetic field in the piston’s flow channels. The MR fluid changes its viscosity, from a liquid to a semi-solid, when subjected to a magnetic field.

In these terms, the piston acts as a “magnetorheological valve”, and the damping is the result of the friction between the fluid and the flow channel. By controlling the characteristics of the magnetic field, the damping behavior is easily adjustable without the need to change the mechanical setup of the system.

What makes InvShock unique?

How we deliver higher performance, durability, safety & comfort

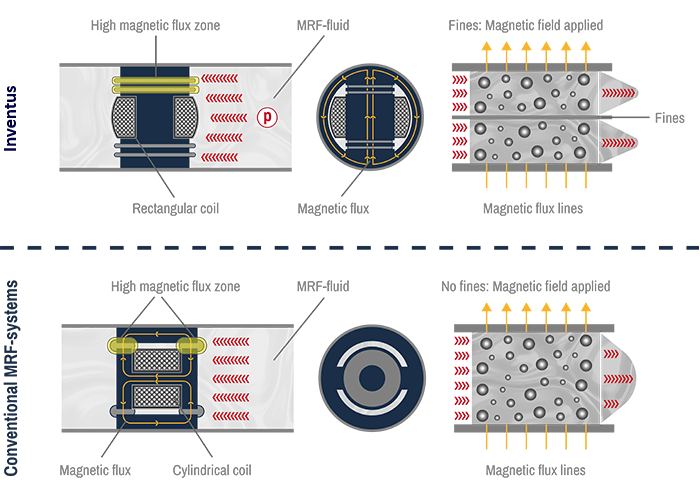

The difference lies within the valve design. InvShock uses a different coil orientation in the valve for a longer magnetized flow channel.

The channel diameter is also reduced through fins that decrease plug size at the end of each flow channel. Paired with our high-resolution sensor concept, InvShock is the only system that allows for real-time adaptivity.

Our patented valve design also delivers:

- increased performance

- decreased energy consumption

- reduced overall size of the system

FULL POWER AT 12 V

Low system requirements without performance compromises

InvShock adapts perfectly to the circumstances of any situation thanks to its fast response time, high dampening power, and precise level of control. But the system requires only a 12-volt power supply – regardless of system size and without performance compromises.

Advanced Features

The InvShock technology allows for so much more than motion control and reduced vibrations. Its real-time adaptivity paired with freely programmable damper characteristics enables revolutionary new features and advanced functionalities that open up entirely new possibilities and fields of application.

Full lockout

InvShock systems can create a full lockout at any position, effectively locking the damper in real-time.

InvShock full lockout

Other systems

Data logging

Due to our patented sensor design, InvShock can not only adjust its behavior via software in real-time but also log real-time data.

These data sets can then be evaluated to detect misuse, track wear and tear or analyze system failure and unprecedented situations.

InvShock data logging

Hard & soft stops

InvShock doesn’t just allow you to set end stops at custom immersion depths but to program the hardness of stops easily via software.

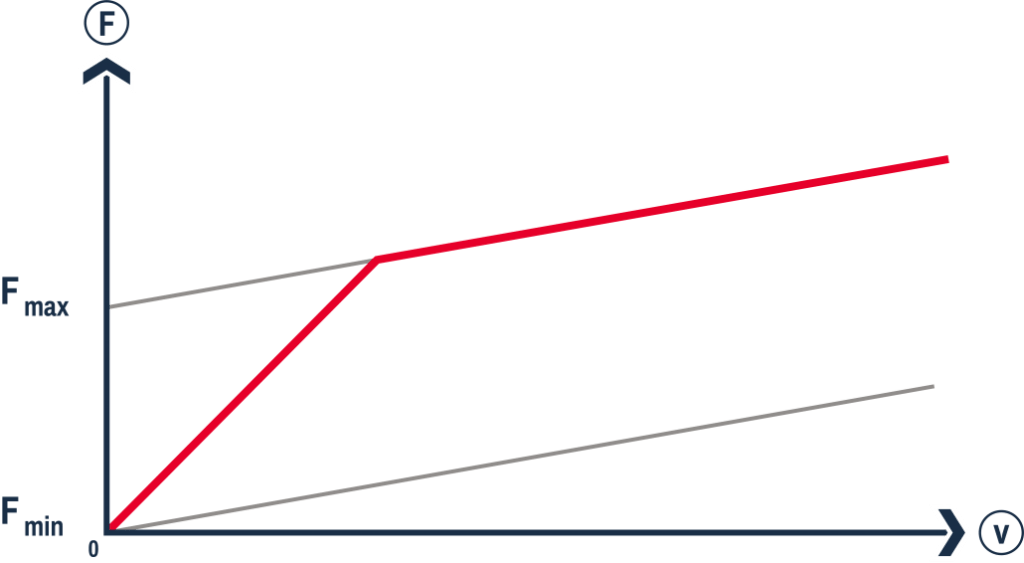

This feature enables you to emulate rubber bearings if required.

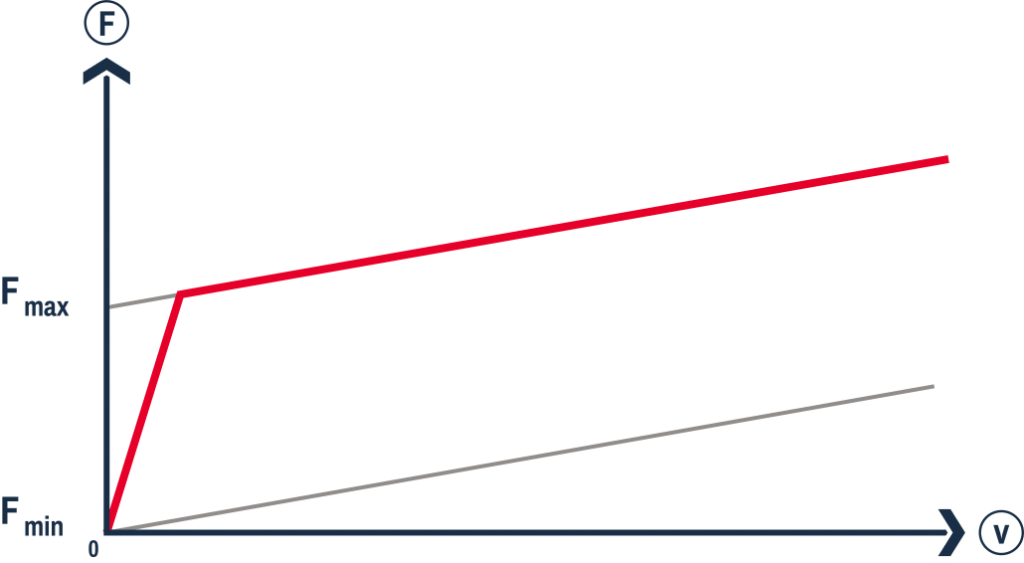

Hard Stop

Soft Stop

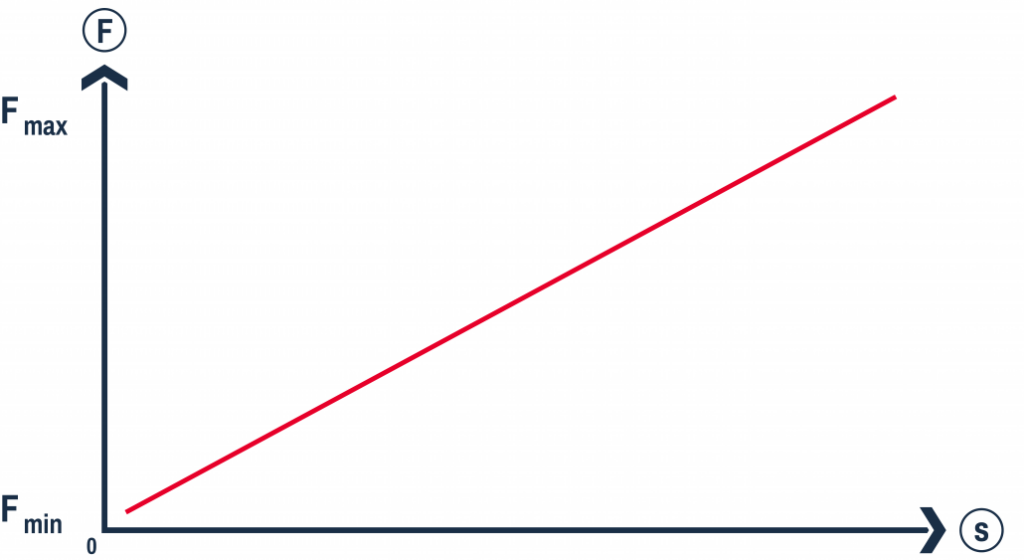

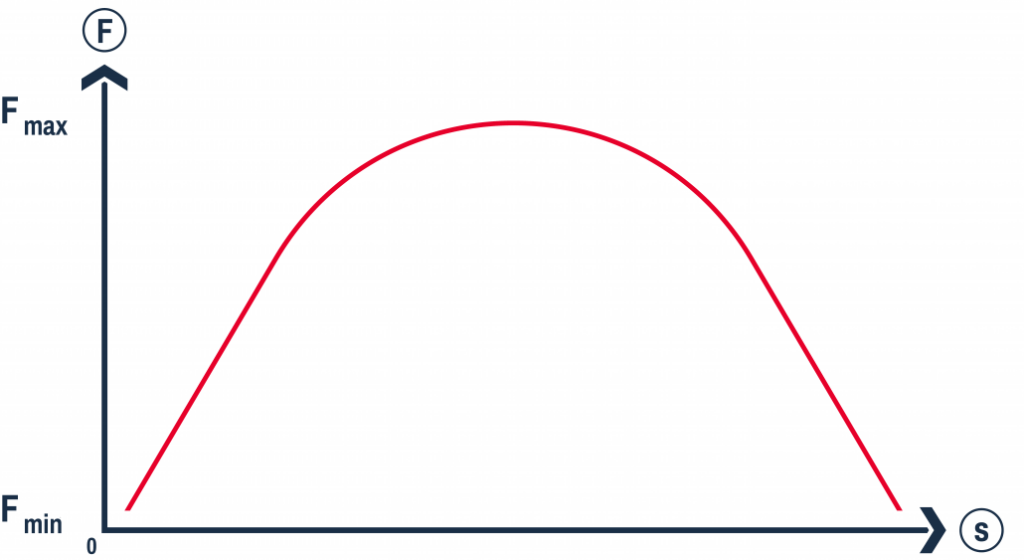

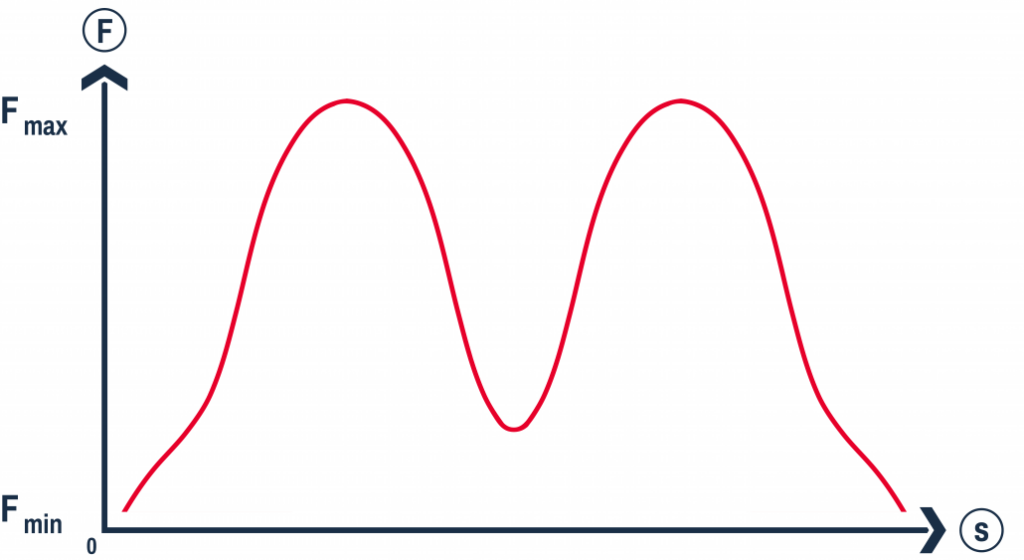

Programmable resistance

The real-time adaptivity of InvShock allows you to increase and decrease the damper resistance in any configuration.

Increasing resistance

Curved resistance

Custom resistance

Hold function

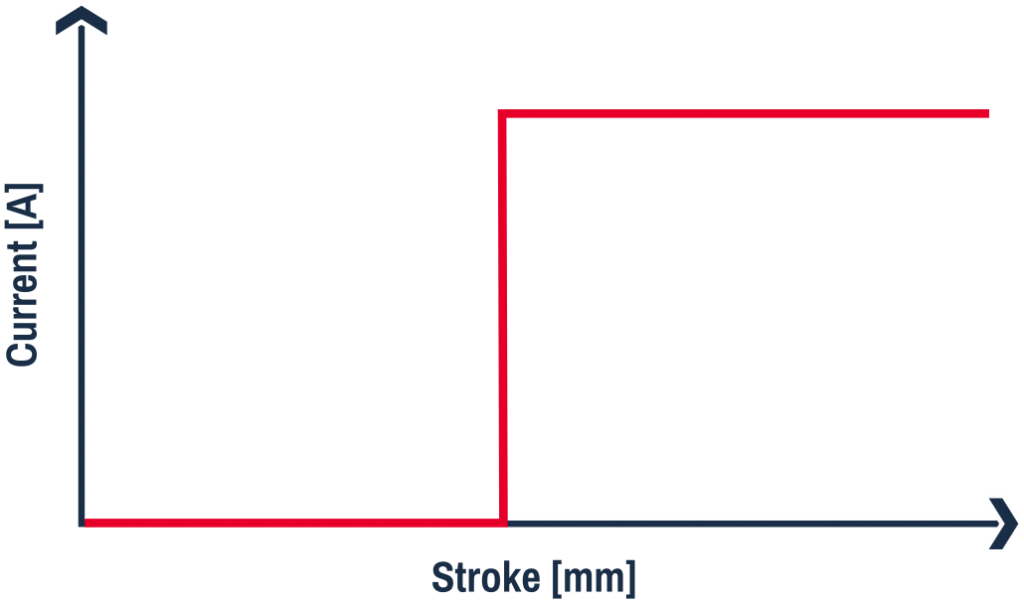

A special feature of InvShock is the hold function. With it, the piston rod can be held at a certain immersion depth and released via software.

Hold function

Real-Time Adaptivity

Without the need to look ahead

InvShock uses a patented Hall sensor with a resolution of 1 µm and a sample rate of 12 kHz. This is so fast, that we can detect movement and vibration changes at the moment they occur. It is also why we do not need to look ahead to adapt to any situation in real-time. But, this fast recognition is just the first step toward our real-time adaptivity.

The system only becomes real-time capable through the use of our MR technology. Through our valve design, we are able to create a magnetic field along the whole flow channel in about 3 ms. The iron particles in the MRF react to this magnetic field and narrow or even fully block the flow channels to change the damping behavior. This whole process barely takes 10 ms.

The combination of sensors paired with our valve design and the MR material is the key to our real-time adaptivity.

Learn more about INVSHOCK

Learn more about our INVSHOCK technology and MR Materials or request a free technology demonstration.

Do you have questions? Get in touch with us, our support team will be happy to assist you.