Adaptive

Rotary Damper

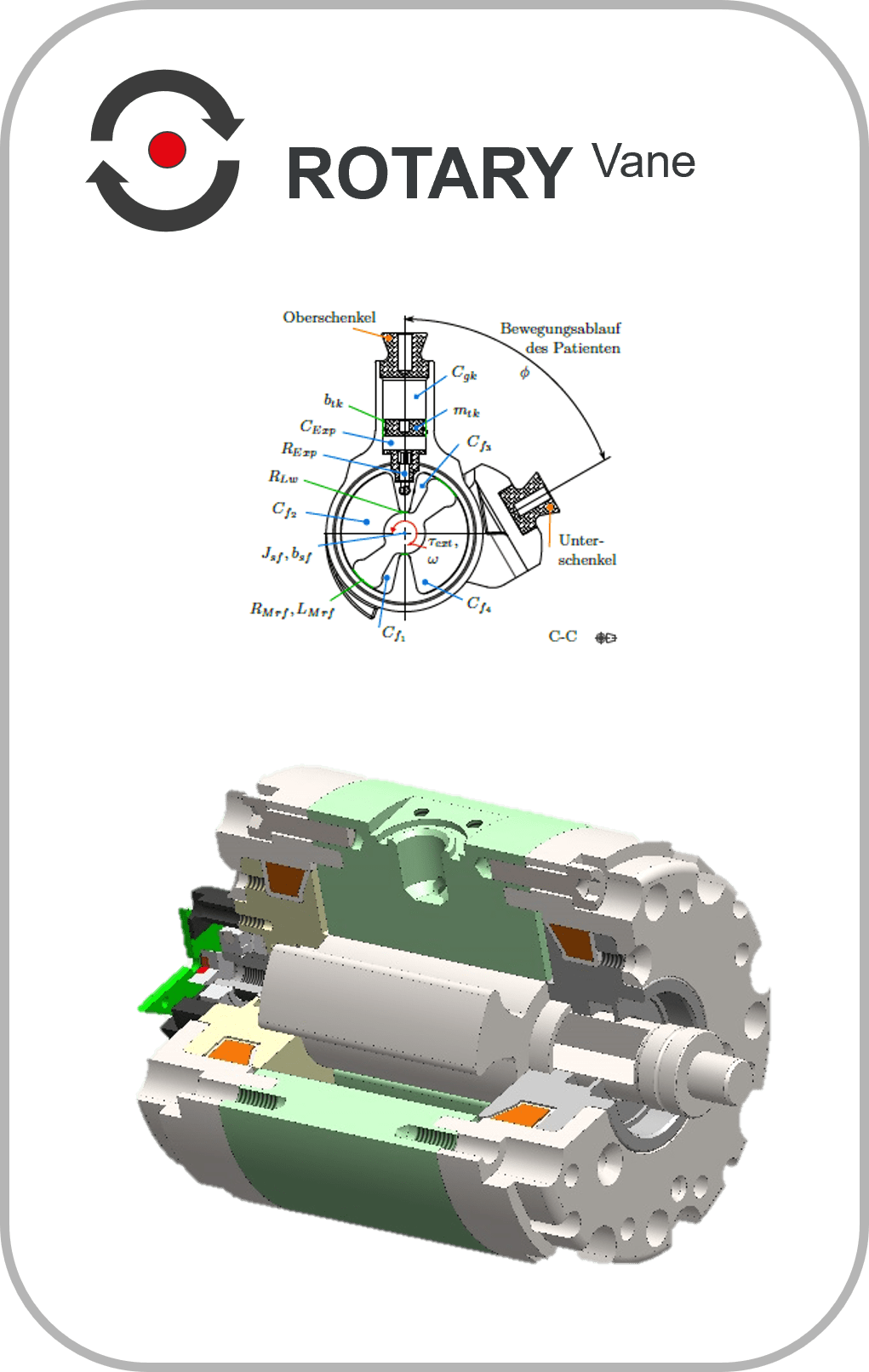

INVENUTS Rotary Vane

WEBSITE UNDER CONSTRUCTION

Revolutionary rotary dampers: Magnetic sealing instead of expensive seals – durable, low-maintenance and leak-free!

Durability and maintenance-free operation

Reliable tightness

Compact design

The problem and how to solve it

The Problem: Leaky Seals in Rotary Dampers

Traditional rotary dampers, while compact and efficient, suffer from a critical flaw: seal leakage. These dampers rely on seals to contain pressurized fluid, but these seals are prone to wear and tear, leading to:

- Costly maintenance: Frequent replacement of seals adds to the overall expense.

- Performance degradation: Leaks reduce damping efficiency, compromising performance.

- Reliability issues: Unexpected failures due to leakage can cause safety concerns

This problem has plagued industries ranging from automotive to prosthetics, limiting the potential of rotary dampers.

The Solution: INVENTUS‘ Magnetic Seal

Inventus has engineered a groundbreaking solution: magnetic sealing. By harnessing the power of magnetism, we’ve eliminated the need for traditional seals altogether. This revolutionary approach offers:

- Unmatched durability: No more wear and tear, resulting in significantly longer service life.

- Absolute leak prevention: A hermetically sealed system ensures consistent performance and reliability.

- Reduced manufacturing costs: Simplified design with fewer components and less stringent manufacturing tolerances.

Our magnetorheological rotary damper represents a paradigm shift in damping technology, offering superior performance, reliability, and cost-effectiveness.

Consists of:

Magnetic and better tightness

No sealing lips

Integrated valve

Reduced production costs

Design

INVENTUS-Project

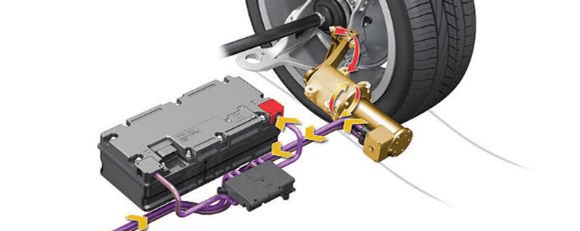

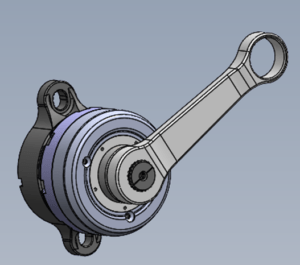

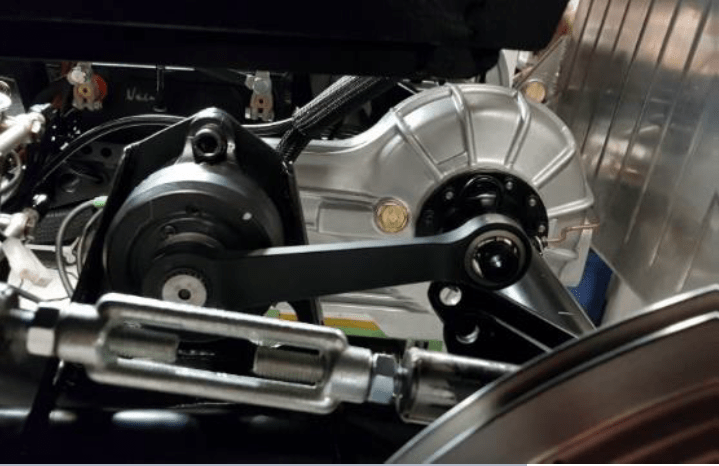

The INVENTUS „Rotary vane“ operating principle as a swivel vane structure for chassis dampers enables high torques in a small installation space. The INVENTUS „Rotary Vane“ was also designed as an adaptive roll stabilizer and tested in a BMW X6 over several thousand kilometers.

The torque:

> 200nm possible | scalable

(in combination with a special planetary gear we have achieved > 1,000 Nm)